The second floor of the CRF houses the Cell Therapy Unit (CTU). In terms of manufacturing capacity, this is one of the largest facilities of its kind in Europe, with capacity to produce more than six final products simultaneously and with potential for production of around 1,000 therapies annually.

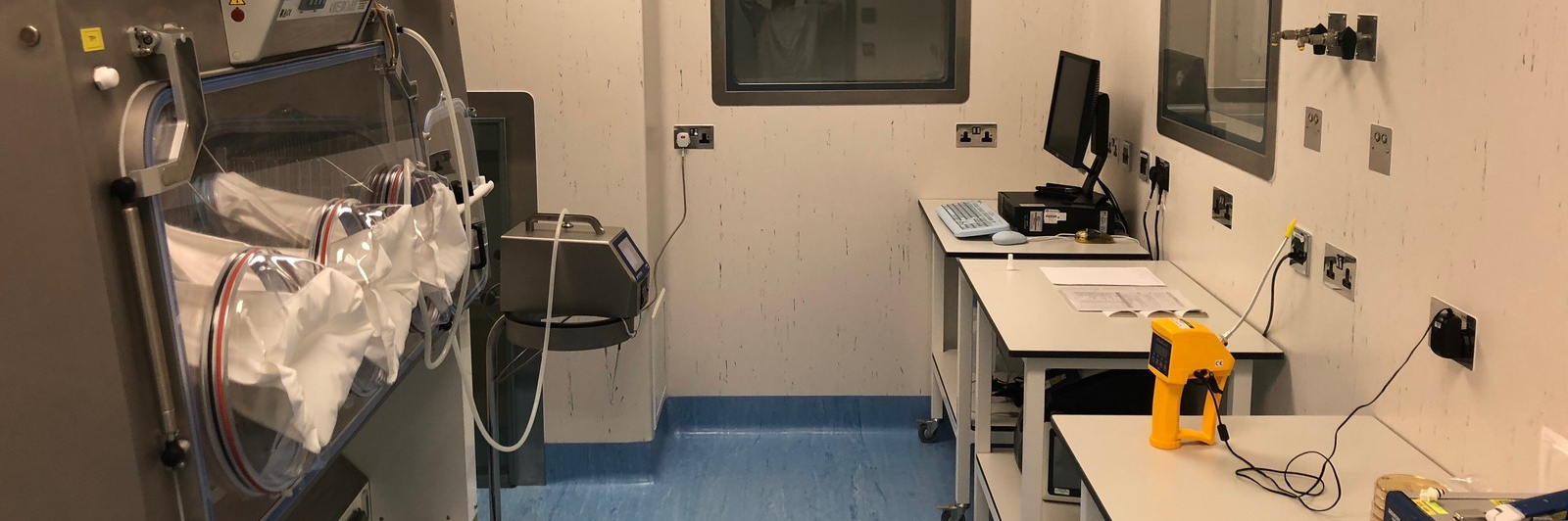

The CTU is a complex and sophisticated Good Manufacturing Practice (GMP) Unit for the manufacture of human cell and gene-based therapies. It is built to the exacting standards required to meet the licensing requirements of the MHRA, HTA and JACIE.

This GMP facility with three process suites contains:

- Grade B suite with closed processing in 1 Grade A isolator: Hepatocytes and Islets cell isolation

- Grade D suite with closed processing in 3 Grade A isolators: Cell Therapy (BMT & MSC)

- Grade D suite with closed processing in 2 Grade A isolators: Cell & Gene Therapy

- Additional controlled rate freezer room for cell freezing

- Controlled non-classified area comprising cryostore (sited on Ground floor), cold pack, prep and waste treatment

Common area & sample handling (outside CTU):

- QC lab

- Changing rooms

- Meeting room

- Write up room/hot desk area

- Staff refreshment room

- GMP Storage Facility

CTU Director: Professor Anil Dhawan

CTU Quality Director: Penny Bligh

Facility Manager: Jonathan Foster

Senior Lab Technician: Laura Tolley

Lab Technician: Ayesha Khatun